Wicking beds are an effective, hands-on teaching tool that introduce students to gardening while supporting learning in Mathematics, Science, and English. They also form part of teaching students how to plan, manage, and run a project. We hope that when students grow up, they will remember that growing vegetables at school was fun.

In this article, we will build a wicking bed that complies with school regulations but also works great for home gardens and small commercial businesses.

Choosing and Preparing the Site

Find a position that gets at least six hours of sunlight per day in winter (e.g., north-facing), with easy access and near a tap. Ensure the ground is level and avoid windy areas or ‘wind tunnels.’

Prepare the site by removing any sharp objects. Use carpet or sand to protect the liner from sharp objects. If nut grass is present, place a metal sheet beneath the bed.

Involving the Groundskeeper

Try to get the groundskeeper involved and keep him/her informed. They can provide valuable knowledge and assistance, and it can help to prevent costly mistakes. For example, in one school, a wicking bed liner was folded down for easy filling, but that required the entire bed to be dug out and filled again. Keeping the groundskeeper informed from the start helps to ensure the beds remain free from accidental sprays.

If you’re lucky, they may also look after your bed over the holidays!

Picking Your Bed Size

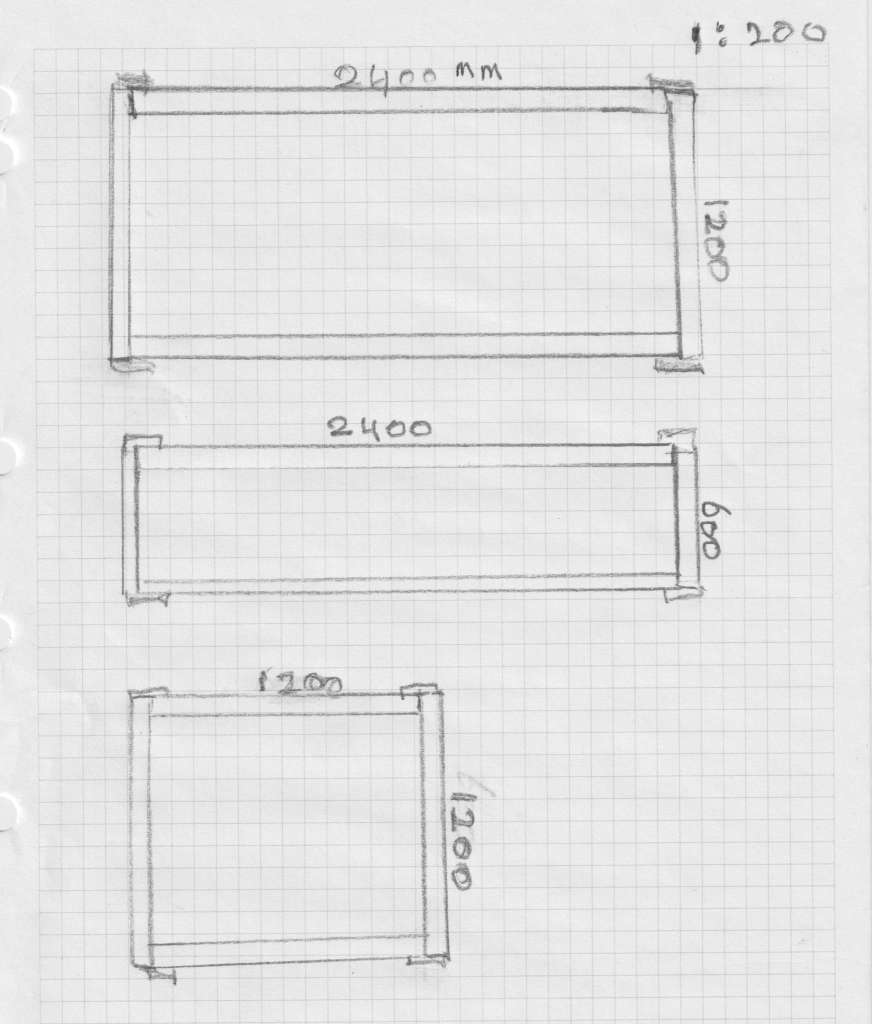

There are three suitable bed sizes for schools:

- Long Narrow Bed: 2,400 mm x 800 mm (easier for smaller children)

(We tried 600mm to avoid any waste of timber but prefer 800mm as it allows rows of different crops along the length and looks better.) - Long Wide Bed: 2,400 mm x 1,200 mm (allows more crops but needs longer arms).

- Square Wide Bed: 1,200 mm x 1,200 mm (smaller but more flexible for instance to give small groups their own bed for their own project).

Materials and Equipment

Frames

Use Micro PRO Sienna treated pine, available in sleepers of 2,400 mm x 200 mm x 50 mm. Request pre-cut planks for easier transport.

- Long Narrow Bed: Five sleepers of 2,400 mm, one cut into three 800 mm pieces, and one into an 800 mm length and a spare 1,600mm length.

- Long Wide Bed: Four sleepers of 2,400 mm and four of 1,200 mm.

- Square Wide Bed: Eight sleepers of 1,200 mm.

Note: Treat all cuts with wood preservative for longevity.

Joint Covers

To cover and reinforce the joints at the outside of the bed use ACQ-treated decking timber or hardwood (90 mm wide, four lengths of 400 mm). Reinforcement inside the bed is not desirable as it has sharp edges that eventually can cut through the plastic liner. It is also harder to do.

Liner

To make the bed water and leakproof, use Concrete Underlay AS 2870 (double-layer 200-micron, 2,000 mm wide rolls). Use it as double layer for ease of cutting and for extra thickness. It should cover the floor and four sides.

- Long Narrow Bed: 3,100 mm x 1,600 mm

- Long Wide Bed: 3,100 mm x 2,000 mm

- Square Wide Bed: 2,000 mm x 1,900 mm

Water Storage

The water storage is 90 mm PVC stormwater drain pipe:

- Long Wide Bed: Two lengths of 500 mm, one length of 2,000 mm, one length of 2,100 mm

- Long Narrow Bed: One length of 500 mm, one of 900 mm, one elbow, one end cap, one screen cap (to stop mosquitoes)

- Square Wide Bed: Two lengths of 500 mm, one of 900 mm, one of 1,000 mm, three elbows, one end cap

Fittings

All beds need:

- A screen cap on the inlet pipe (prevents mosquitoes)

- One tank outlet (as used in metal water tanks)

- 180 mm of 12 mm poly pipe for inside the bed

- 30 mm of 12 mm poly pipe for outside the bed

Fasteners

- 16 batten screws (18-8 × 100 mm)

- 32 batten screws (10-8 × 40 mm)

Tools

- A piece of lino with one straight edge, a pencil, and an elastic band (to mark the pipes for cutting).

- A hacksaw (to cut the PVC pipes).

- An electric drill

- 60 mm hole-saw (to cut the drainage holes in the PVC pipe)

- 22 mm drill bit (to cut the outlet hole in the timber)

- 12 mm drill bit (to cut a hole in the PVC pipe)

- 6 mm drill bit (to predrill holes for the screws when assembling the timber frame).

- A small pair of pliers (to remove the cut-out bits from the hole-saw).

- A screwdriver (to put the frame together).

- A flat sander (to remove sharp edges, smooth the liner protector, ensure it is splinter-safe and for the bed to look good).

- A rats-tail file (to widen the 12 mm outlet hole in the fill-pipe to 13 mm).

- A pair of scissors (to cut the liner).

- A pair of nail scissors (to cut the outlet hole in the liner).

- Clamps or masking tape (to hold the liner in place while filling the bed with soil).

Building the Bed

Read through the steps first to understand where everything is to go. Measure twice, cut once to avoid waste and mistakes. We learned the hard way.

The Frame

- Use a sander to round all sharp edges to ensure it is splinter-safe and to smooth the surface of the top of the frame.

- Drill a 22mm hole for the tank outlet at the centre of one of the 800mm length and 90mm from the bottom. Mark the top and the bottom of the timber to prevent errors.

- Place two lengths of 2,400mm on a level surface.

- Place one length of 800mm and the length of 800mm with the tank outlet whole between them as per diagram 800. Make sure the hole is near the floor.

- Measure and adjust the distance between opposite corners until they are the same and the sides of the bed are parallel.

- Join each corner with two 100mm batten screws, and the bottom course is done.

- Place corresponding lengths on top and join them the same.

- Use a length of 400 mm decking timber at each corner to cover the joints and to keep both courses together by providing vertical rigidity, using eight 40mm screws per corner, four screws for the top and four for the bottom course.

Building the Water Reservoir (90mm PVC drainpipe and fittings)

- Mark and cut one length of 500mmn and one length of 2,000mm PVC Pipe

- In the 2,000m length, drill a 60mm hole 150mm from the end, then another six others 300mm apart.

- Put the 500mm length onto the elbow and drill a 12mm hole as shown in the photo.

- Use rats-tail file to widen it to 13 mm to ensure a tight fit of the poly pipe

- Place the screen cap on top of the inlet pipe and the end cap at the end of the water reservoir.

The Overflow

(Note: The washers that come with the tank outlet are to be discarded.)

- Push the 120mm length of poly pipe onto the tank outlet.

(Some brands of poly pipe have thicker walls and may be hard to push onto the tank outlet. If so, hold that end of the pipe under a hot water tap to soften it.) - Put the short ends of poly pipe onto the 90° degree bend

(By swivelling it upwards, the water level in the beds can be raised, for instance at the start of very hot long weekends)

The Liner

- Cut a liner 3100 x 1,600 mm from a roll or a bought length and lay it on a floor.

- Fold-in the long sides by 400 mm and press hard to get a sharp crease.

(The lengthwise folding must be done first so that, when opened, the excess liner in the corners will sit against the long side and not be in the way for the overflow.) - Fold-in each end by 400 mm and press hard.

- Place the liner in the bed.

- Fold the liner folded upwards and secure it with duct tape until the bed is filled with soil.

- Push a pencil or similar pointed object through the hole and the plastic, then enlarge that to a 24 mm diameter hole using small scissors. (Cut away the excess material, don’t fold it back.)

- Push the tank outlet and poly pipe from the outside through the timber and the plastic and screw the nut on at the inside.

- Place the water reservoir in the bed and push the hole in the upright for half or more over the polypipe into. (Make double sure the 90° degree angle is facing down.)

- Push one of the poly pipes attached to the 900 bend into the outside tank outlet.

The bed is now ready to be filled

- After a few weeks of growing, the soil and liner will have settled, and the liner can be cut to below the soil level as the plastic will deteriorate over time in the sun.

Adding the Soil

Now that your bed is ready, you’ll need to fill it. If you already grow vegetables, use soil from your best existing beds. If you have to buy soil, see the Soils for Wicking Boxes and Tubs for how to prepare ‘good’ soil for best growth.

You will need 1,000L (one cubic metre) for a long wide bed and 500L (half a cubic metre) for the long narrow bed or the square wide bed.